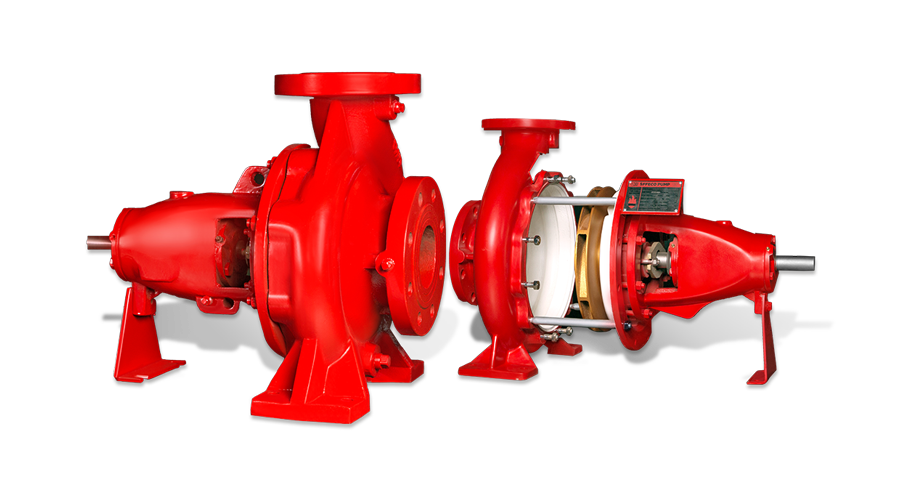

Certified End Suction Fire Pumps

For any interests or questions regarding SFFECO products & services, please click below.

Send EnquiryCentrifugal End Suction Fire Pumps

Our End Suction Fire Pumps are UL Listed & FM Approved and are in compliance to NFPA 20 Design Requirements. The fire Pumps come in a wide range of Flows and pressures. All SFFECO End Suction pumps pass through rigorous Hydrostatic & Performance test, as required by global standards. These Fire pumps are available in Electric Motor & Diesel Engine Driven configurations.

Technical Data Table

The range of End Suction Fire Pumps has a wide range of models, which come in varied flows & pressures. For more detailed information please contact our sales team or you can download our Catalog from below.

NOTE:

- All Pumps are Hydrostatically Tested to minimum of 150% of its Maximum Working Pressure and can withstand Double the Max.Working Pressure.

- All Pumps have Clock-Wise Rotation when viewed from the Driver Side.

- All Pumps are horizontal single stage Pumps.

- “The rated speed marked on the pump can vary within +/-4% of the listed/ approved rated speed example: 3000 RPM pump can be driven with 2900 RPM Drivers.”

| Model No. | Rated Capacity (GPM) | Size(SucXDis) (inches) | UL Listed Rated Net Pressure Range (PSI) | FM Approved Rated Net Pressure Range (PSI) | SETSCO & CE Pressure(PSI) | Approx Speed (RPM) | Max Working Pressure (PSI) |

|---|---|---|---|---|---|---|---|

| SFP-50-20 EM-2G | 50 | 2 ½ X 2 | 74 - 93 | 74 - 93 | 74 - 93 | 2900 | 180 |

| SFP-50-20 EM-2G | 50 | 2 ½ X 2 | 79 - 99 | 79 - 99 | 79 - 99 | 3000 | 180 |

| SFP 50-20 EM | 50 | 2 x 1 ¼ | 68 - 87 | 68 - 88 | 68 - 87 | 2900 | 230 |

| SFP 50-20 EH | 50 | 2 x 1 ¼ | 101 -129 | 102 - 129 | 101 -129 | 3500 | 230 |

| SFP 50-26 EM | 50 | 2 x 1 ¼ | 115 -140 | 115 - 133 | 115 -140 | 2900 | 230 |

Features

- Dynamically Balanced Impeller extends bearing life and ensures smoother operation.

- Foot Supported Casing eliminates need to support casing when bearing assembly is removed.

- Top Centerline Discharge transmits residual pipe strain to feet of casing and eliminates the need for left-handed or right-handed casings and impellers.

- Simpler Installation & Piping Layout via top centerline discharge with base supported casing.

- Back Pullout Design supplied with spacer coupling ensures easy pump maintenance without Dismantling.

--

- Frame-mounted design.

- Self-Venting Design eliminates vapor lock and the need for automatic air release valve.

- Efficiently Designed Shaft to minimize shaft deflection at the stu‑ng box.

- Small Footprint ideal for retrofit.

- Heavy Wall Thickness to provide for generous corrosion allowance.

- Heavy Duty with integral flush line for packing lubrication.

- Lip Seals on each bearing housing cap to keep out contaminants.

- Back Pump Out Vanes prohibiting material from building up behind impeller.