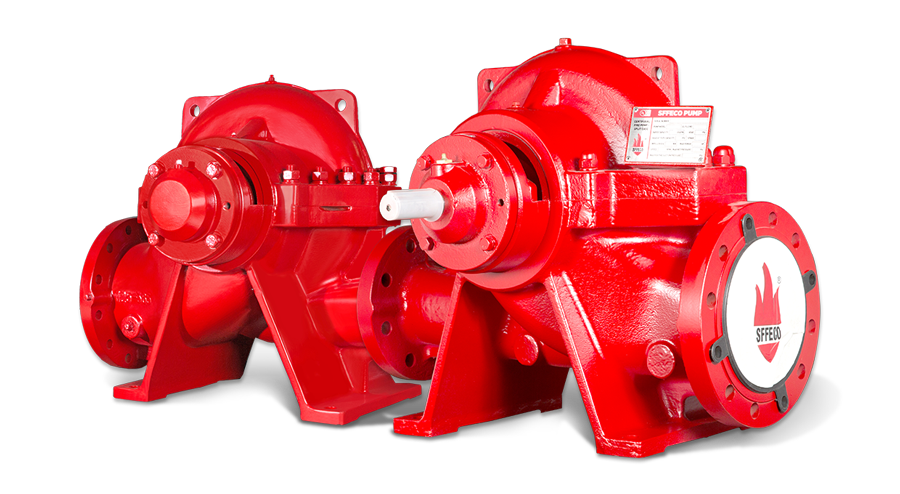

Certified Horizontal Split Case Fire Pumps

For any interests or questions regarding SFFECO products & services, please click below.

Send EnquiryCentrifugal Horizontal Split Case Fire Pumps

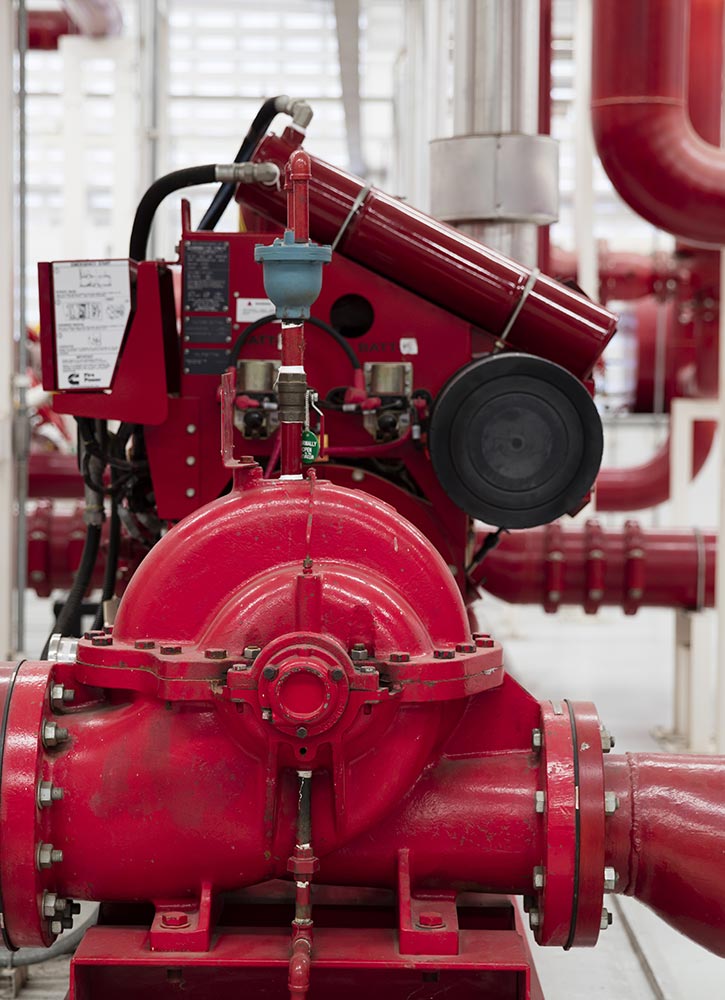

Our Horizontal Split Case Fire Pumps are UL Listed & FM Approved and are in compliance to NFPA 20 Design Requirements. The fire Pumps come in a wide range of Flows and pressures ranging from 150 psi to 2000 psi. All SFFECO Split Case Pumps pass through rigorous Hydrostatic & Performance test, as required by global standards. These Fire pumps are available in Electric Motor & Diesel Engine Driven configurations.

Technical Data Table

The range of Horizontal Split Case Fire Pumps has a wide array of models, which come in varied flows & pressures. For more detailed information please contact our sales team or you can download our Catalog from below.

NOTE:

- All Pumps are Hydrostatically Tested to minimum of 150% of its Maximum Working Pressure and can withstand Double the Max.Working Pressure.

- All Pumps have Clock-Wise Rotation when viewed from the Driver Side.

- All Pumps are horizontal single stage Pumps.

- “The rated speed marked on the pump can vary within +/-4% of the listed/ approved rated speed example: 3000 RPM pump can be driven with 2900 RPM Drivers.”

| Model No. | Rated Capacity (GPM) | Size (SucXDis) | UL Listed Rated Net Pressure Range (PSI) | FM Approved Rated Net Pressure Range (PSI) | SETSCO & CE Rated Net Pressure Range (PSI) | Approx Speed (RPM) | Max Working Pressure (PSI) |

|---|---|---|---|---|---|---|---|

| SFP150-25SH | 150 | 6 x 4 | 114-208 | 114-208 | 114-208 | 3500 | 300 |

| SFP150-25SH | 150 | 6 x 4 | 121-220 | 121-220 | 121-220 | 3600 | 300 |

| SFP150-40SM | 150 | 6 x 4 | 206-289 | 206-289 | 206-289 | 2900 | 385 |

| SFP150-40SM | 150 | 6 x 4 | 221-310 | 221-310 | 221-310 | 3000 | 385 |

| SFP150-SN31SH | 150 | 6 x 4 | 226-316 | 226-316 | 226-316 | 3500 | 405 |

Features

- Horizontal Split for easy access.

- Dynamically Balanced double suction impellers extend bearing life and ensure smooth operation.

- Casing with Thru-Bore allowing Easy Removal of the entire rotating assembly, including both stuffing boxes, and the entire bearing housing assembly.

- Volute Type Casing with double suction provides suction and discharge nozzles cast integral with the lower half of the casing.

- Both the Inboard & Outboard Bearing can be completely replaced without disturbing any other part of the rotating assembly, due to the Cartridge bearing arrangement.

- Suction & Discharge Gauges with shut-off cocks.

- Renewable casing wear rings, for Easy Maintenance and proper running clearances.

- Casing Wear Rings allow smooth transfer of fluid into impeller eye, increasing efficiency & lowering NPSH.

--

- Lower Initial Cost

- Rugged Construction

- Liberal water passages

- Efficient Operations

- Grease Lubrication

- Heavy wall thickness to provide for generous corrosion allowance and high working pressures.

- Heavy Dury outboard bearing fixed rigidly in housing to take end thrust load.

- Lip Seals for both bearings protects the bearing housing from contaminants

- Suction & Discharge connections placed in lower half, allows removal or inspection of upper half and rotating assembly without disturbing piping or driver.